Timber Frame Wall Systems

Timber Frame

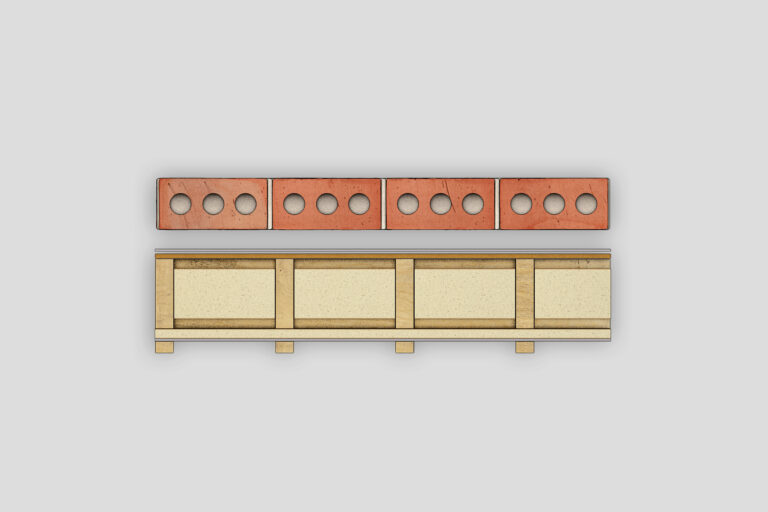

ULTIMATE Wall System

The Taylor Lane Timber Frame ULTIMATE wall system is for those seeking the very best in future-proofed timber frame technology. Manufactured with factory precision, this closed panel reduces cold bridging and offers enhanced thermal and air tightness performance.

Under the Modern Methods of Construction (MMC) definition framework the ULTIMATE is categorised as MMC Category 2 – Pre-manufacturing (2D primary structural systems).

For more information including psi and U-values, please get in touch.

Technical Details

| Breather Paper | External reflective breather (factory-fitted) |

| External Sheathing | 9mm OSB sheathing (factory-fitted) |

| Stud Size | 140mm |

| Stud Insulation | 80 or 100mm factory-fitted |

| Additional Insulation | 25 or 50mm factory-fitted |

| Vapour Control Layer (VCL) | Internal Reflective VCL |

| Service Battens | 25 x 38mm timber batten |

| U-Value Range (W/M²K) | 0.12 - 0.15 - based on external masonry finish |

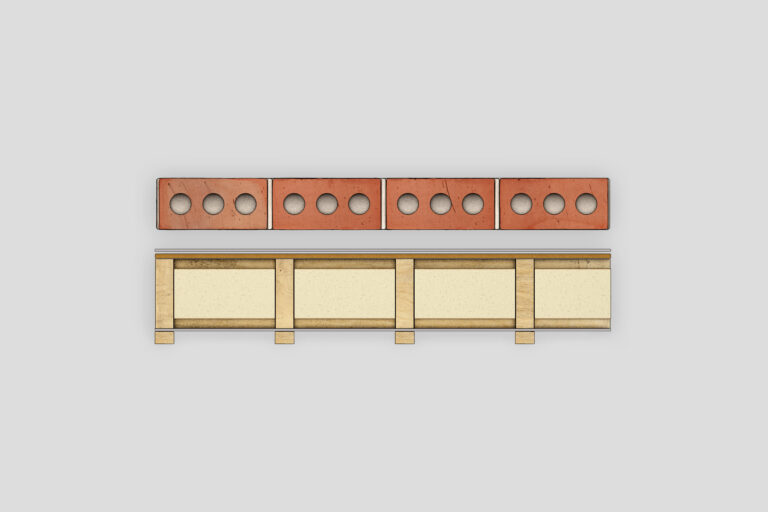

Timber Frame

ADVANCED Wall System

Under the Modern Methods of Construction (MMC) definition framework the ADVANCED wall system is categorised as MMC Category 2 – Pre-manufacturing (2D primary structural systems).

For more information including psi and U-values, please get in touch.

Technical Details

| Breather Paper | External reflective breather (factory-fitted) |

| External Sheathing | 9mm OSB sheathing (factory-fitted) |

| Stud Size | 140mm |

| Stud Insulation | 80 or 100mm factory-fitted |

| Vapour Control Layer (VCL) | Internal Reflective VCL |

| Service Battens | 25 x 38mm timber batten |

| U-Value (W/M²K) | 0.17 and 0.18 - based on masonry external finish |

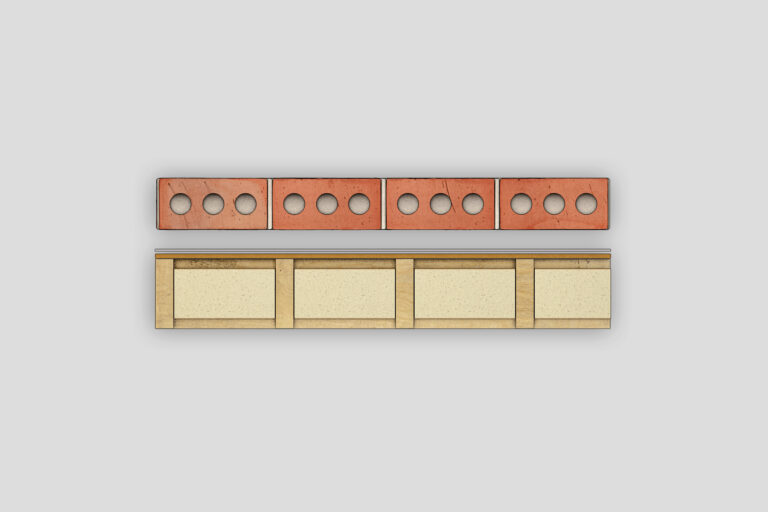

Timber Frame

CLASSIC Wall System

Under the Modern Methods of Construction (MMC) definition framework the CLASSIC wall system is categorised as MMC Category 2 – Pre-manufacturing (2D primary structural systems).

For more information including psi and U-values, please get in touch.

Technical Details

| Breather Paper | External reflective breather (factory-fitted) |

| External Sheathing | 9mm OSB sheathing (factory-fitted) |

| Stud Size | 140mm |

| Stud Insulation | 100mm factory-fitted |

| U-Value (W/M²K) | Dependent upon finishes. Email sales@taylor-lane.co.uk for guidance. |

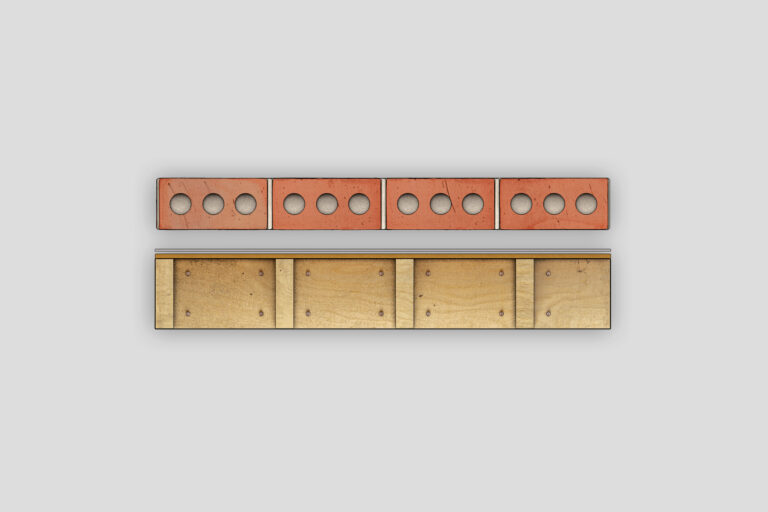

Timber Frame

FIRST Wall System

Under the Modern Methods of Construction (MMC) definition framework the FIRST wall system is categorised as MMC Category 2 – Pre-manufacturing (2D primary structural systems).

For more information including psi and U-values, please get in touch.

Technical Details

| Breather Paper | External reflective breather (factory- fitted) |

| External Sheathing | 9mm OSB sheathing (factory-fitted) |

| Stud Size | 140mm |

Products